Produk

Tungsten Solid Carbide Rods

Deskripsi Carbide Rods

Batang karbida tungsten digunakake kanthi wiyar kanggo nggawe alat karbida padat premium, kayata pabrik pungkasan, pengeboran, reamers, pemotong panggilingan, stamping, lan alat ukur ing industri sing beda-beda. Alat Kedel ngasilake rod karbida kualitas ndhuwur lan konsisten ing macem-macem gelar kalebu K20F, K25F, lan liya-liyane. Pilihan standar lengkap rod tungsten karbida ing macem-macem dimensi kasedhiya, lan kita uga nawakake layanan kustomisasi miturut syarat sampeyan. Minangka pabrikan ISO, Kedeltool nggunakake bahan sing paling apik kanggo njamin kualitas lan kinerja rod karbida. Kanthi pemeriksaan kualitas sing ketat, kita bisa njamin kualitas sing konsisten ing saben batch.

Jinis Rod Karbida Kedel

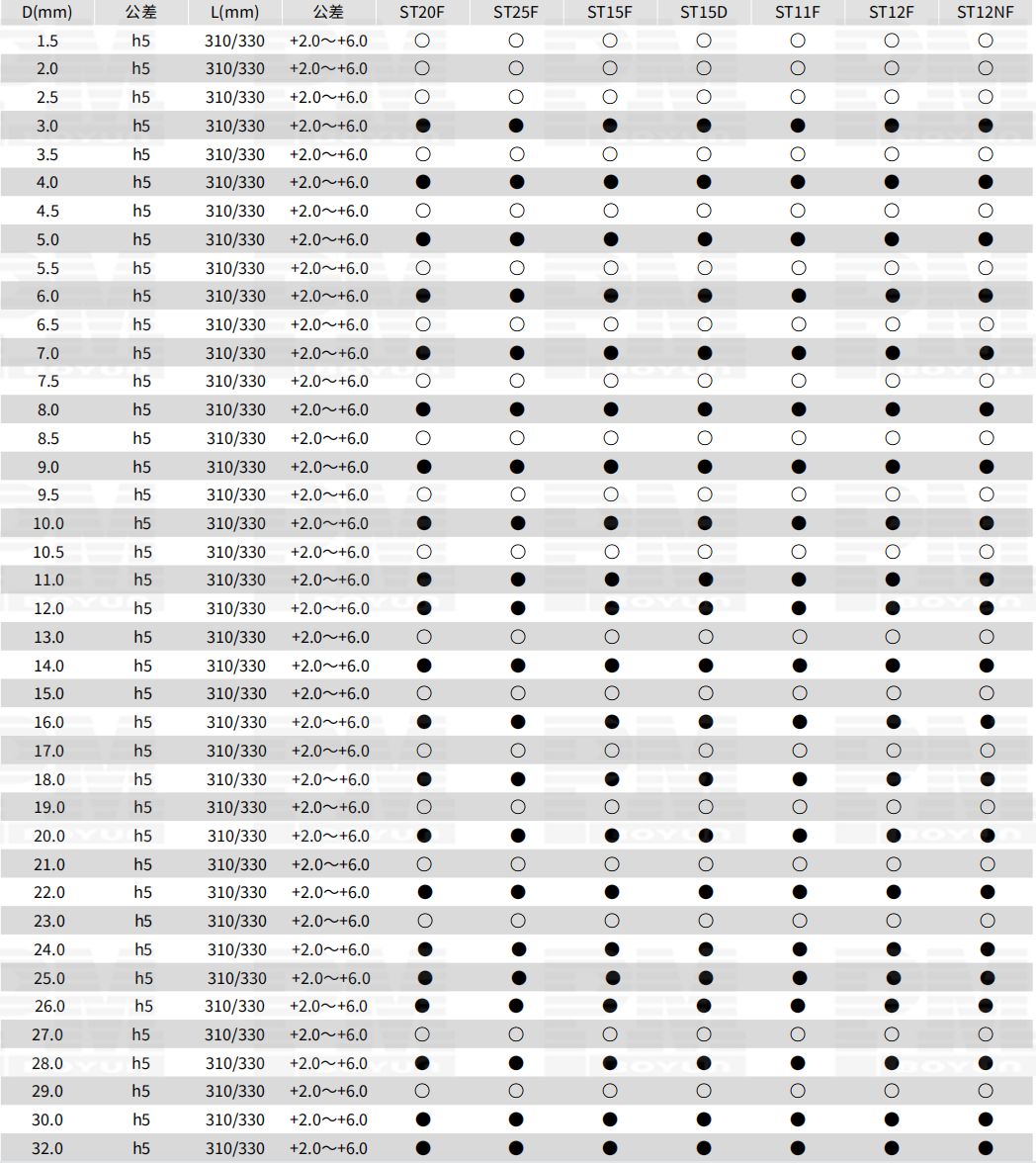

1. Rod Karbida Padat ing Metrik

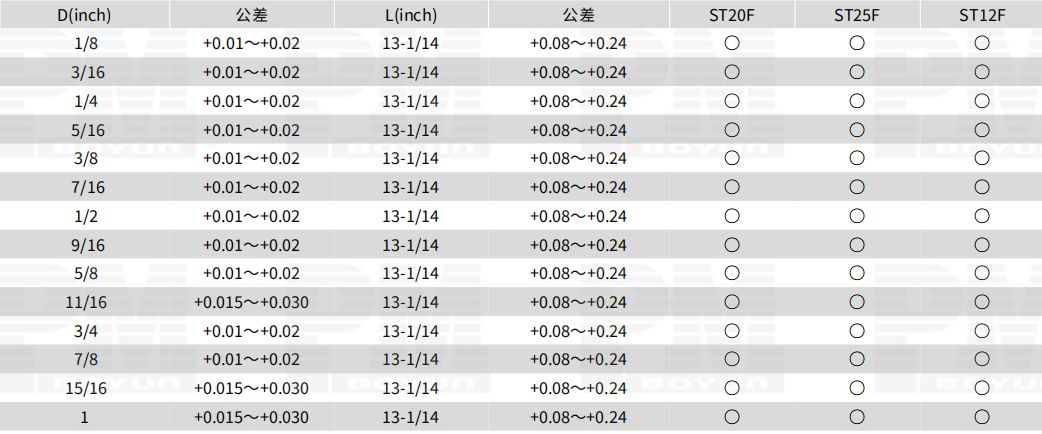

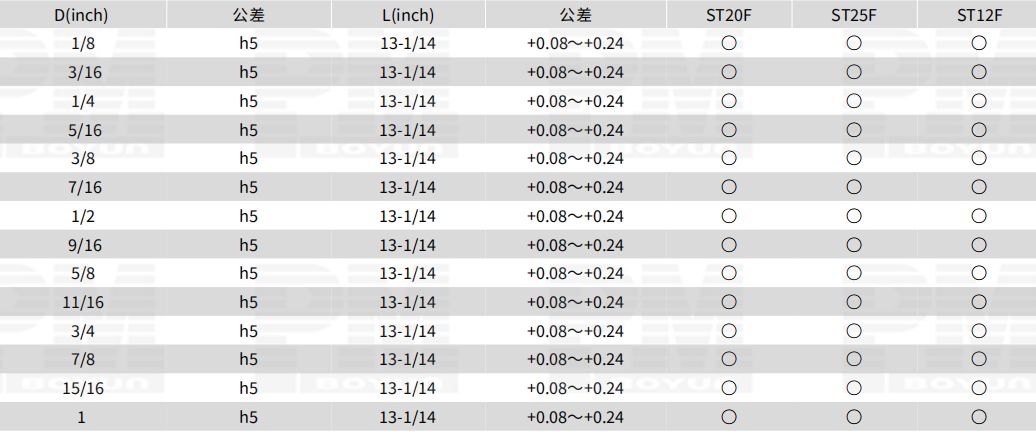

2. Solid Carbide Rod ing Inci

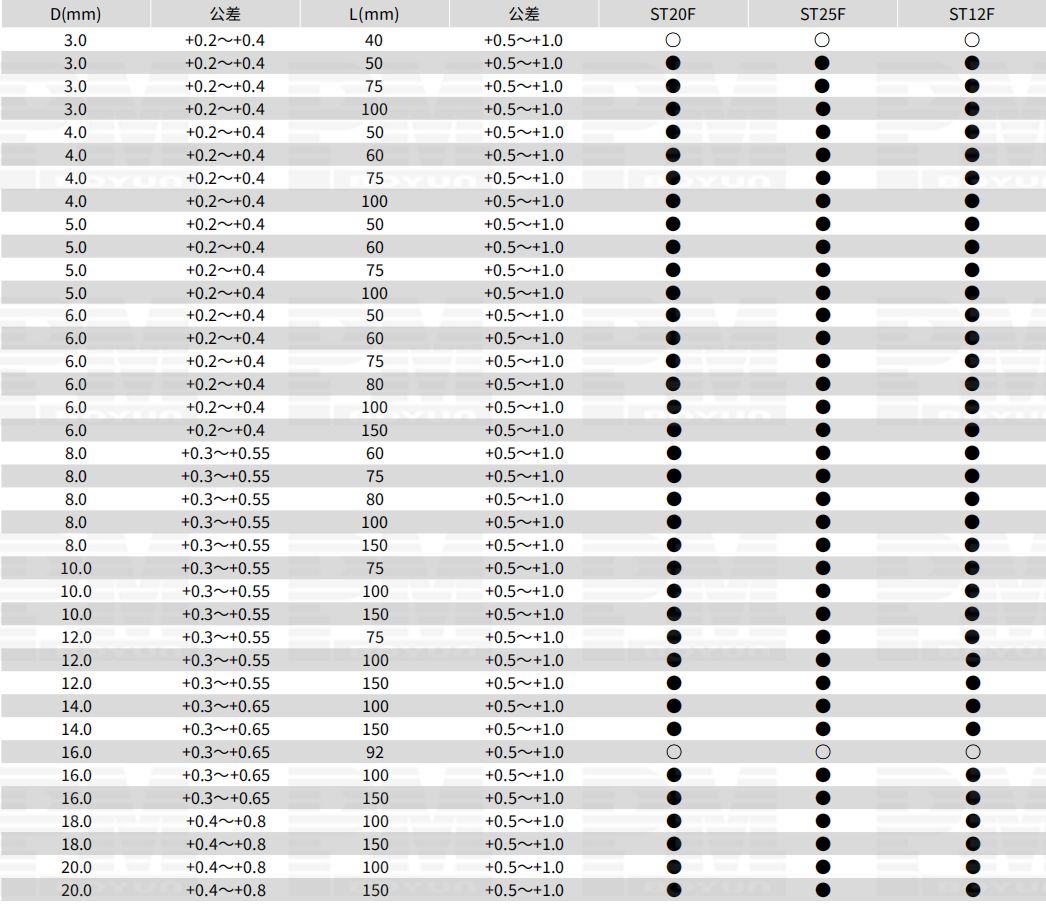

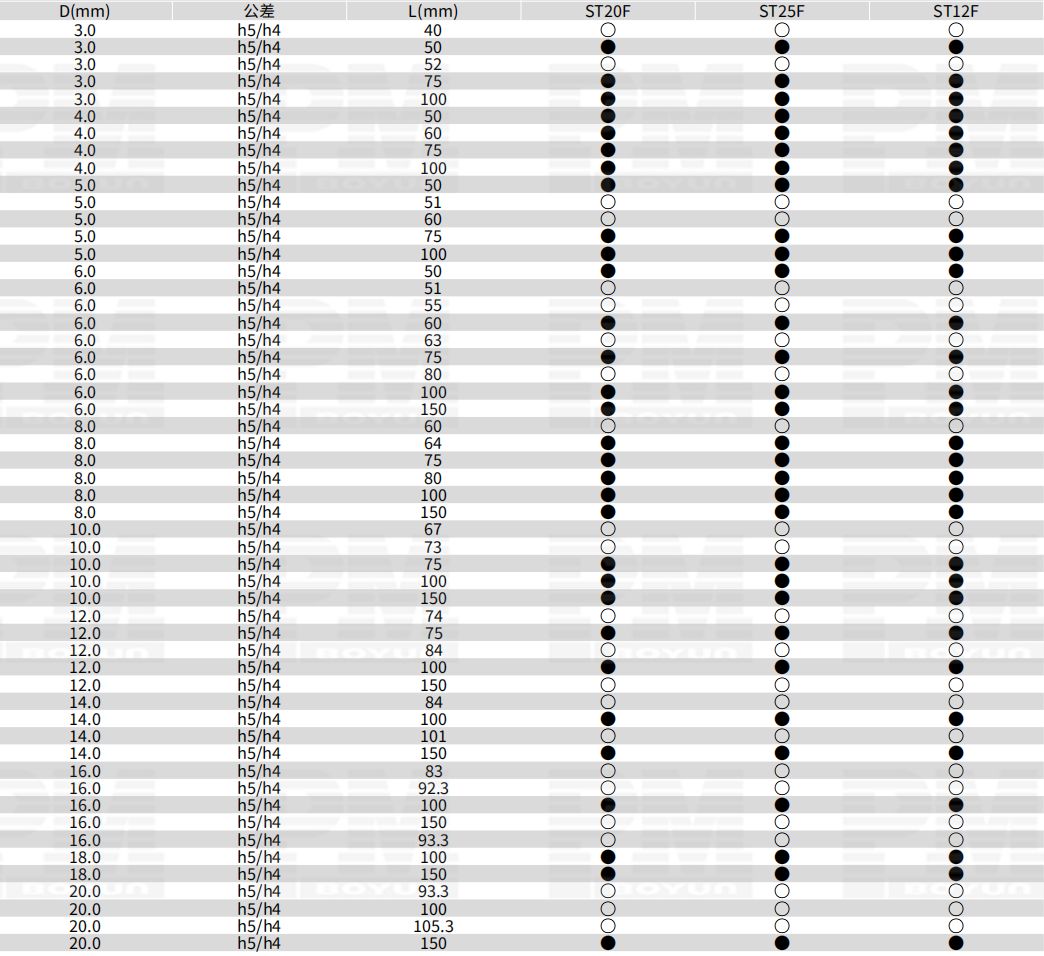

3. Bor Kosong (Chamfered)

4. End Mill Kosong (Chamfered)

5. Carbide Rod karo Lurus Coolant Tengah Lubuk

6. Carbide Rod karo Loro Lurus Coolant bolongan

Karakteristik Karbida Rod

1. Digawe dening kualitas dhuwur tungsten carbide wêdakakêna superfine

2. peralatan Precision karo 10MPa HIP-Sinter kompor standar Pabrik.

3. kekerasan dhuwur lan kekuatan dhuwur

4. Kaluwihan khusus: kekerasan abang, tahan nyandhang, modulus elastisitas dhuwur, TRS, stabilitas kimia, tahan impact, koefisien dilatasi kurang, konduksi panas lan konduksi listrik padha karo wesi.

5. Teknologi khusus: sintering tekanan dhuwur saka vakum suhu dhuwur. Ngurangi porositas, nyuda kompak lan sifat mekanik. Macem-macem kelas, jinis lan ukuran.

6. Kelas sing beda kanggo referensi sampeyan.

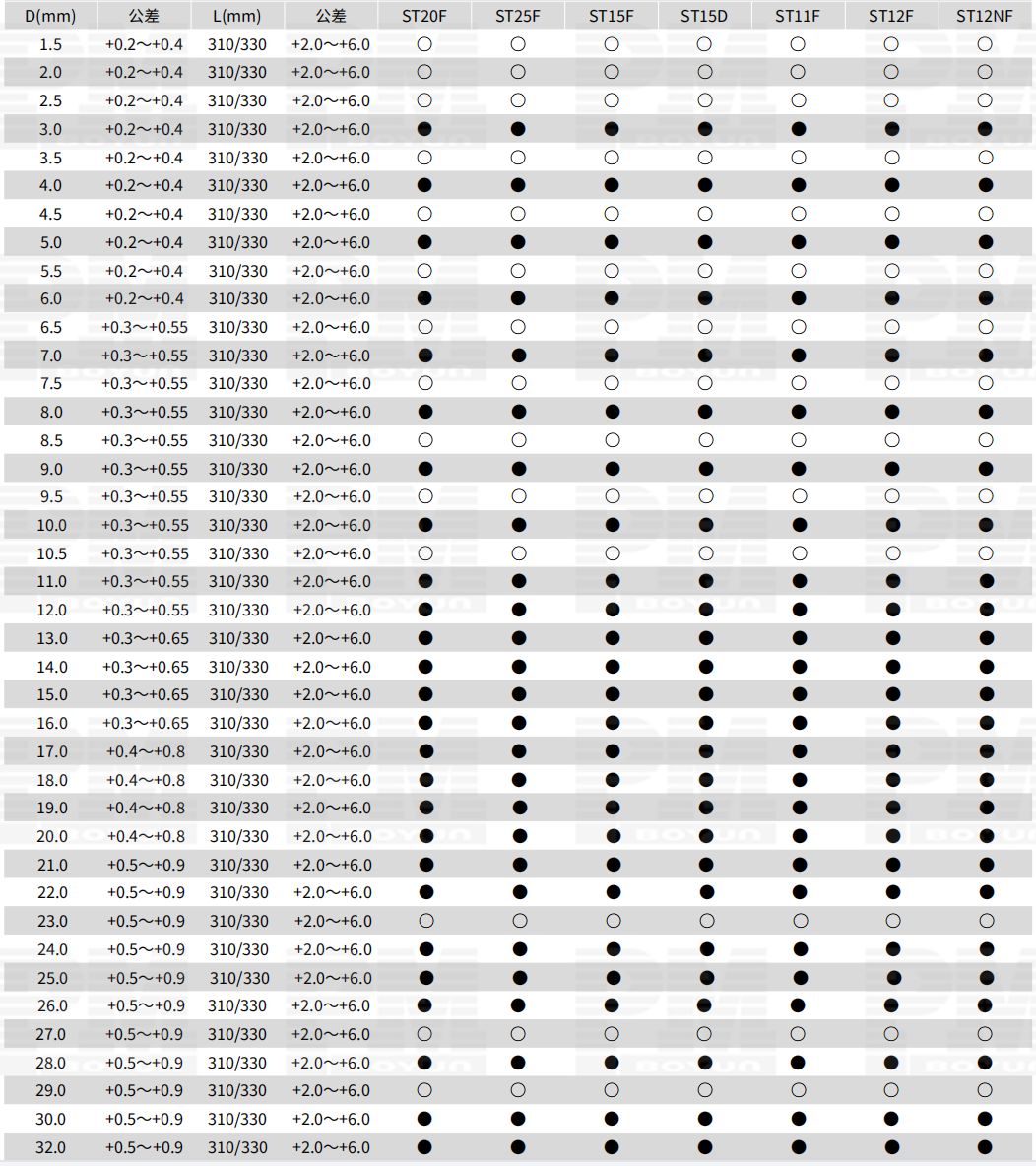

Ukuran Umum

Daftar Kelas

| Grade Pambuka kanggo Carbide Rods | |||||||

| sasmita | Co% | WC ukuran gandum | HRA | HV | Kapadhetan (g/cm³) | Kekuatan lentur (MPa) | Ketangguhan patah (MNm-3/2) |

| KT10F | 6 | Submicron | 92.9 | 1840 | 14.8 | 3800 | 10 |

| KT10UF | 6 | superfine | 93.8 | 2040 | 14.7 | 3200 | 9 |

| KT10NF | 6 | nanometer | 94.5 | 2180 | 14.6 | 4000 | 9 |

| KT10C | 7 | nggih | 90.7 | 1480 | 14.7 | 3800 | 12 |

| KT11F | 8 | Submicron | 92.3 | 1720 | 14.6 | 4100 | 10 |

| KT11UF | 8 | superfine | 93.5 | 1960 | 14.5 | 3000 | 9 |

| KT12F | 9 | superfine | 93.5 | 1960 | 14.4 | 4500 | 10 |

| KT12NF | 9 | nanometer | 94.2 | 2100 | 14.3 | 4800 | 9 |

| KT15D | 9 | Submicron | 91.2 | 1520 | 14.4 | 4000 | 13 |

| KT15F | 10 | Submicron | 92.0 | 1670 | 14.3 | 4000 | 11 |

| KT20F | 10 | Submicron | 91.7 | 1620 | 14.4 | 4300 | 11 |

| KT20D | 10 | Submicron | 92.0 | 1670 | 14.3 | 4500 | 11 |

| KT25F | 12 | superfine | 92.4 | 1740 | 14.1 | 5100 | 10 |

| KT25EF | 12 | superfine | 92.2 | 1700 | 14.1 | 4800 | 10 |

| KT25D | 12 | superfine | 91.5 | 1570 | 14.2 | 4200 | 13 |

| KT37NF | 15 | nanometer | 92.0 | 1670 | 13.8 | 4800 | 10 |

Kanggo informasi luwih lengkap (MOQ, rega, pangiriman) utawa yen sampeyan butuh layanan kustomisasi, nyuwun penawaran.