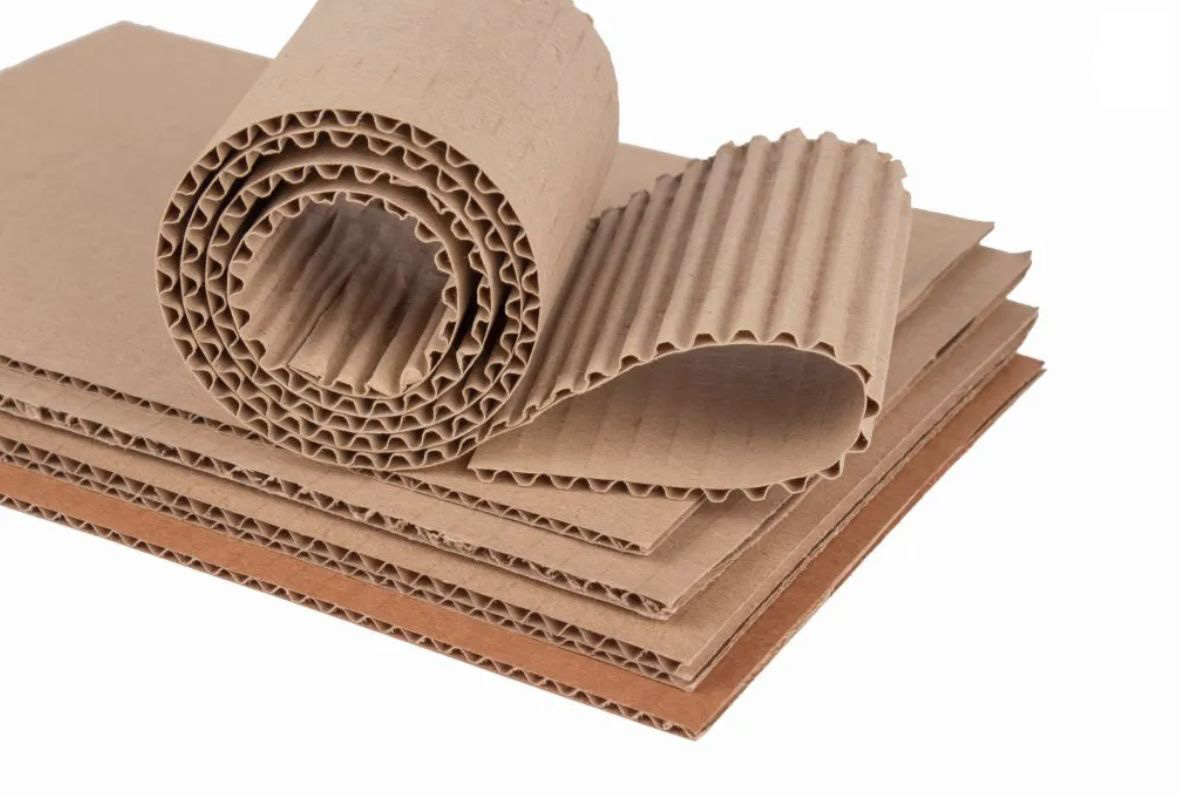

Produk

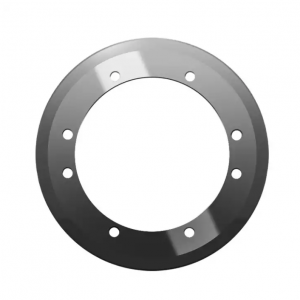

Pisau bunder slitting kertas corrugated

Deskripsi Produk

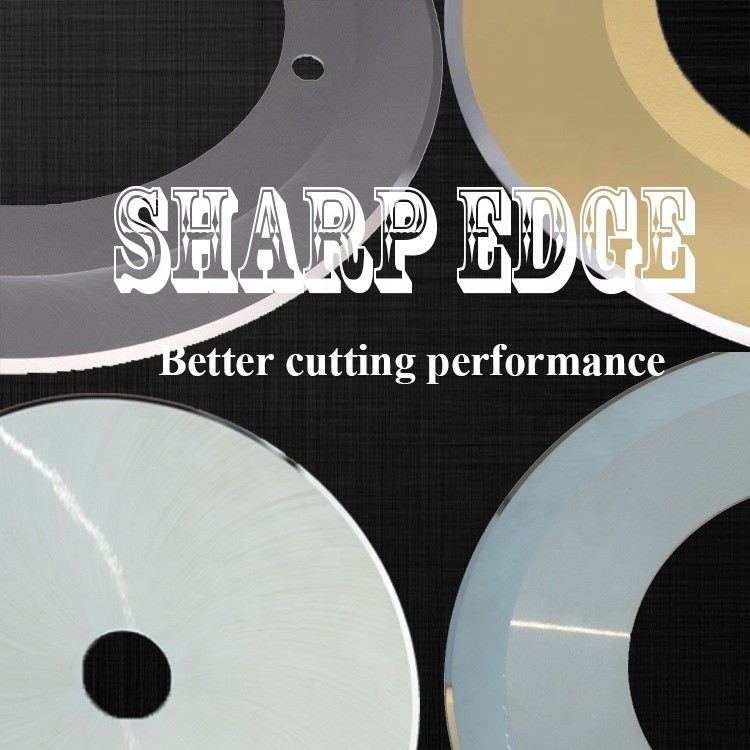

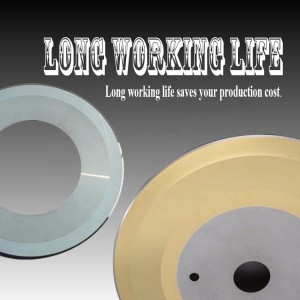

Pemotong kertas karbida semen digawe saka bahan karbida semen padhet. Nduwe karakteristik kekerasan sing dhuwur, resistensi nyandhang dhuwur, umur layanan sing dawa, lan liya-liyane. Iki digunakake kanthi akeh ing merek mesin pemotong kertas kanthi efisiensi pemotongan sing dhuwur.

| Merk | KEDEL |

| Negara Asal | Cina |

| Bahan | M2, HSS, TCT lan Priksa grafik ing ngisor iki |

| Ukuran | Ukuran umum, Customized |

| Kekerasan | TCT: HRA 89~93, Baja perkakas: HRC62~65 |

| Kemasan | kothak kayu karo film anti-karat nang |

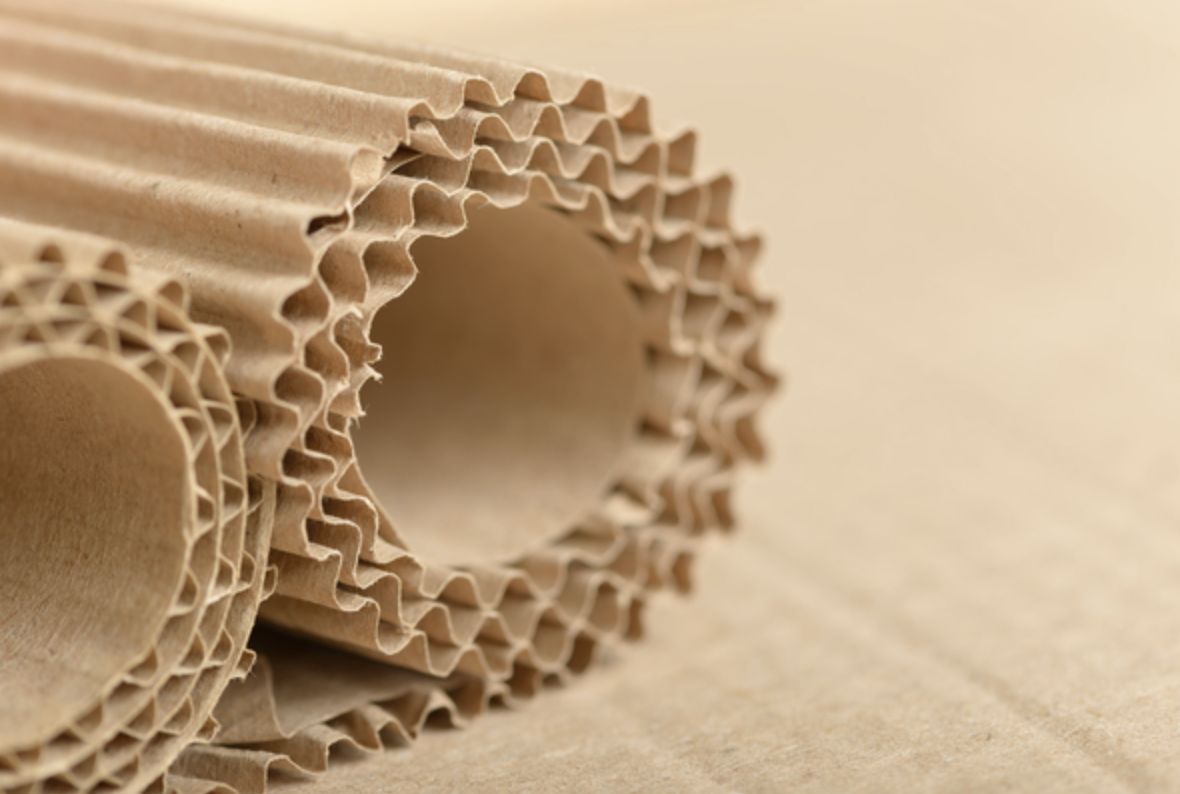

| Aplikasi | Kanggo mesin slitter |

Daftar Bahan

| KELAS ISO | KEKUATAN (HRA) ± 0,5 | KEDADHAN (g/cm³) ± 0,2 | TRS (MPa) | APLIKASI |

| K10 | 92.8 | 14.75-14.90 | 2400 | Gandum sub-micron, cocok kanggo nglereni paperboard, serat optik, kulit. Aplikasi kanggo ngrampungake mesin saka logam non-ferrous lan piranti woodworking. |

| K05 | 92.3 | 14.55-14.7 | 2500 | Gandum sub-micron, ditrapake kanggo nglereni bahan komposit, mesin finishing logam non ferrous lan alat woodworking. |

| K20 | 91.3 | 14.55-14.7 | 2500 | Gandum sing apik, utamane digunakake kanggo agul-agul kayu lan mesin pemotong rokok. |

| K20-K30 | 91.8 | 14.35-14.50 | 3000 | Gandum sub-mikron, ditrapake kanggo nglereni papan bergelombang, serat kimia, plastik, kulit, potongan kutub baterei, kabeh knids pemotong panggilingan lan alat mesin bolongan. |

| K10-K20 | 92.5 | 13.95-14.10 | 3500 | Gandum ultra-fine, ditrapake kanggo nglereni papan corrugated, paerboard, kulit, bahan komposit, mesin saka wesi cor abu-abu lan alloy tahan panas. |

| K40 | 90.5 | 13.95-14.10 | 3200 | Gandum sub-micron, resistance abrasive lan kateguhan paling apik, ditrapake kanggo pemotong kayu, nglereni papan corrugated, bêsik pole baterei etc. |

Ukuran Umum

| Ukuran (mm) | Merk Mesin |

| 260x158x1.35-22° | Justu |

| 260x158x1.3-22° | Justu |

| 200x122x1.3-22° | Justu |

| 260x158x1.5-22° 8-Φ11 | Justu |

| 260x158x1.35-22° 8-Φ11 | Justu |

| 200x122x1.2-22° | Justu |

| 200*122*1.5-Ora ana | Justu |

| 240x32x1.3-20° 2-Φ8.5 | BHS |

| 240x32x1.3-28° 2-Φ8.5 | BHS |

| 240x32x1.2-28° 2-Φ8.5 | BHS |

| 230x135x1.1-16° 4-UR4.25 | Fosber |

| 230x135x1.1-17° | Fosber |

| 230x110x1.1-17° 6-Φ9.0 | Fosber |

| 230x110x1.3-14° 6-Φ9.5 | Fosber |

| 230*135*1.1-6xΦ9 | Fosber |

| 240x115x1.2-18° 3-Φ9 | Agnati |

| 240x115x1.0-18° 3-Φ9 | Agnati |

| 240*115*1-Ora ana | Agnati |

| 260*168.3*1.2-Ora ana | Marquip |

| 260*168.3*1.5-Ora ana | Marquip |

| 260*168.3*1.3-Ora ana | Marquip |

| 260*168.3*1.2-8xΦ10.5 | Marquip |

| 260*168.3*1.5-8xΦ10.5 | Marquip |

| 270*168*1.5-8xΦ10.5 | Hsieh Hsu |

| 270*168*1.3-8xΦ10.5 | Hsieh Hsu |

| 270*168*1.3-Ora ana | Hsieh Hsu |

| 270*168.3*1.2-8xΦ8.5 | Hsieh Hsu |

| 270*168.3*1.5-8xΦ10.5 | Hsieh Hsu |

| 280*160*1-6xΦ7.5 | Mitsubishi |

| 280*202*1.4-6xΦ8 | Mitsubishi |

| 270×168.3×1.5-22° 8-Φ10.5 | Hsieh Hsu |

| 270×168.2×1.2-22° 8-Φ10.5 | Hsieh Hsu |

| 230x110x1.35-17° | Kaituo |

| 250*105*1.5-6xΦ11 | Jingshan |

| 260*114*1.4-6xΦ11 | Wanlian |

| 300*112*1.2-6xΦ11 | TCY |

Aplikasi

Tulis pesen ing kene lan kirim menyang kita